When 224 Valkyrie was announced in late 2017, I found the cartridge to be somewhat intriguing: .22 caliber based cartridge designed to shoot the heaviest of the .22 caliber bullets at a relatively high speed with a cartridge overall length that will fit in an AR-15 magazine (usually accepted as being ~2.260″).

I had been recently pondering building a .223 Remington bolt rifle with a high twist barrel to shoot 90gr bullets, so I started looking at 224 Valkyrie. Later on, I came across 22 Creedmoor which is basically the 6.5mm Creedmoor parent case necked down to .22 caliber. This looked even better than .223 Remington and 224 Valkyrie because of the high speeds that 22 Creedmoor is capable of.

But then I started reading up on the sporadic issues some people have had with the new high speed .22 caliber cartridges, specifically bullet jacket instability. The issue is that some people have been able to spin jackets off of the heavy 90gr Sierra Match King and Berger VLD bullets. The jackets would separate from the lead core in mid-flight. I ended up coming across a post by a prominent figure in the shooting industry whose expertise in ballistics is highly regarded. This figure basically alluded to a 300,000 RPM threshold for bullets, particularly .22 caliber.

If you exceed 300K RPM on specific .22 caliber bullets, the likelihood of jacket separation in flight is significantly increased.

The quick formula for calculating the RPM of a bullet is:

Bullet RPM = MuzzleVelocity * 720 / Twist Rate (in inches)

When I was looking at 22 Creedmoor, I saw people posting incredible muzzle velocities above 3000 feet per second with a 90gr SMK or VLD.

Assuming, 3000 fps in a 1 in 7″ barrel, that would come out to ~308,571 RPM.

3000 * 720 / 7 = ~308,571

If you decide to go with a 1 in 6.5″ twist barrel, the RPM spikes:

3000 * 720 / 6.5 = ~332,307

For me, the whole point of moving up to something like a 22 Creedmoor is to get the 90gr SMK or VLD moving extremely fast to take advantage of the bullet’s ballistic coefficient and maximize efficiency of the bullet.

In order to stay under this supposed 300K RPM rule, that would mean staying at 2700fps in a 1-6.5″ twist barrel. Limiting that muzzle velocity defeats the purpose of going with a larger base/parent case and necking down to .22 caliber.

Of course, I read all the stories of people who have built 22 Creedmoor rifles and are pushing the 90gr bullets at 3000fps and higher without issue. But this uncertainty seems like a moderate to high risk for me in terms of expending time and money to build a bolt rifle for such a chambering. So even though I have an American Rifle Company Nucleus action that still needs to be built, I decided against 22 Creedmoor (or 224 Valkyrie) for that bolt action. Yet, I still have the yearning to at least get into a .22 caliber cartridge that can shoot a 90gr effectively.

Back when I shot competitive High Power Service Rifle, my go to bullet for the slow fire prone stages was the Berger 80gr VLD. I was able to move it at 2700fps in a 20″ 1-7″ barrel without issue. No one that I know of used the Sierra 90gr Match King for Service Rifle because it was not possible to shoot the 90gr in a 20″ barrel at a muzzle velocity that would justify it’s use over an 80gr variant.

Anyway, last month I saw on social media that X-Caliber Barrels was having a sale on some in-stock barrels. Usually, X-Caliber builds to order (including pre-fit, pre-chambered barrels). But apparently, X-Caliber had some barrels in their inventory they were trying to clear out, and some of those happen to be AR-15 barrels chambered in 224 Valkyrie.

I have some AR parts on hand, including the parts to build a new complete rifle, sans barrel. So given the sale price on the X-Caliber barrel I saw, I decided that getting an AR barrel (and bolt) would be the lowest investment opportunity for me to try out 224 Valkyrie.

Thus, I ordered an X-Caliber stainless steel AR-15 barrel chambered in 224 Valkyrie, with a 24″ length, 1-6.5″ twist, SPR contour, and a rifle length +2 gas system.

To be honest, I don’t have any experience with the extended length gas systems on the AR platform. Shooters that use the AR-15 platform in High Power Rifle match category with 24″, 26″, or longer barrels often use the longer gas tube for longer dwell time. I only went this route because at the time I was on X-Caliber’s site, the 224 Valkyrie barrels in-stock had the +2 gas system.

The price of the barrel was $210 shipped. I was able to source an LWRC International bolt in 6.8 SPC from Brownells for $55. I did have to buy a +2 gas tube from White Oak Armament, and I ended up buying an Area 419 HELLFIRE universal adapter to cover the muzzle threads (and for a future install of an Area 419 HELLFIRE brake).

I basically spent about $300 to get the 224 Valkyrie upper up and running using the parts that I had on hand.

Build list (bold items are the items I had to buy for this mini-project):

- Upper: VLTOR MUR-1A

- Barrel: X-Caliber 24″ 1-6.5″ +2 gas tube – $210

- Bolt: LWRC International 6.8SPC (.224 Valkyrie) – $55

- Bolt Carrier: Spikes Tactical complete BCG (minus bolt)

- Gas Tube: White Oak Armament rifle +2 – $12

- Gas Block: Bravo Company Manufacturing Low-Profile

- Handguard: Bravo Company 15″ KMR with V7 Weapon Systems Titanium KMR Barrel Nut

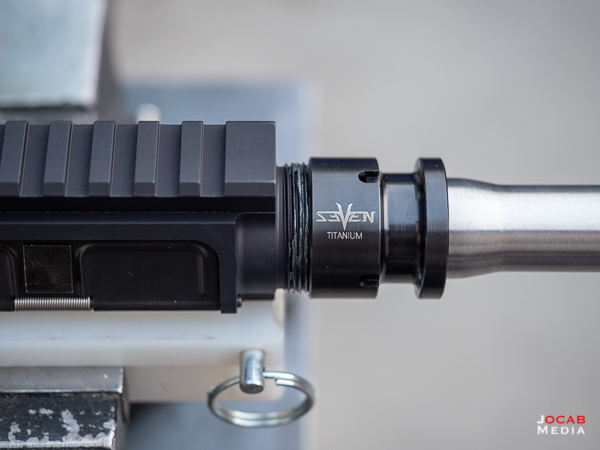

- Muzzle: Area 419 HELLFIRE Universal Adapter – $46

Granted, I technically did not need to buy the Area 419 universal adapter. I could have left the threads exposed (or used an A2 flash hider that I have in my parts kit). But I am leaving myself the option to go with a HELLFIRE muzzle brake on this upper.

I did also spend $40 on top of the parts to get GO and NO-GO gauges for 224 Valkyrie.

I always check headspace on a new AR-15 build / (re)barrel, regardless of manufacturer of the components. Safety is key and the cost of headspace gauges is relatively low. Even a top tier manufacturer could make a run of bolts that are outside of specification and isn’t caught by quality control inspection. It is easier to simply check headspace when assembling.

Installing a barrel on an AR is a straightforward affair. Putting the receiver in a vise, applying AeroShell 33ms grease and torquing the barrel nut to the manufacturer barrel nut manufacturer specification takes only a couple minutes.

I did not pin the gas block and simply relied on the set screws. I do use Loctite 290 (green) on gas block set screws. This stuff is a wicking grade Loctite, so it will seep into the threads and should be applied after the screws are tightened down.

This threadlocker actually works really well for gas blocks and survives heat. For my competition Service Rifles, I also used Loctite 290 on the set screws, but what I also did was put Loctite where the gas block and barrel meet. I let it seep / wick into that space. What ends up happening is that the Loctite 290 dries inbetween the gas block and barrel surface, creating a seal. This helps mitigate gas leaks from the gas block. It also helps create a tighter fit after the gas block is installed.

This does make the gas block more difficult to remove, so I only advise doing this only after the firearm has been tested fired and the gas system is confirmed functional.

As mentioned in the build parts list, I used a Bravo Company Manufacturing (BCM) KMR 15″. This is the original design with the blended aluminum and magnesium alloy that makes for a very lightweight handguard. I am a huge fan of the KMR due to the ergonomics. I simply feels great in the hand. I love the KMR 13″ that I run on my primary carbine, so I bought a KMR 15″ after they became difficult to obtain (due to the alloy being difficult to source). But the KMR 15″ sat in my cabinet because I never had a reason to build a new AR (until now). With the BCM KMR, I did also use a titanium barrel nut specifically for the BCM KMR, but made by V7 Weapon Systems. This also sat in my parts kit waiting to be used on a build.

Then I used a Spikes Tactical complete bolt carrier group that I had in my spare parts kit, and swapped out the .223/5.56 bolt with the 6.8 SPC bolt, of course. A BCMGUNFIGHTER charging handle was also in my spare parts kit and was used for this mini-project build.

I was going to use my Vortex Optics Razor HD Gen 2 4.5-27x56mm EBR-2C MRAD that still sits on my Remington 700 in .308, but I do not own a cantilever mount for a 34mm tube. The Spuhr SP4002 that I have for the Razor HD Gen 2 will not allow adequate eye relief on the AR platform. So I ended up just taking the Vortex Optics Viper PST 2.5-10×32 FFP EBR-1 MRAD off my 18″ SPR and using it for this upper for testing

Note: The Viper PST 2.5-10x32mm was discontinued and replaced by the Viper PST Gen 2 2-10x32mm.

I would certainly have liked more magnification for testing, but it is what it is. I should probably get a Geissele 34mm mount just for this type of application. Of course, I could have taken the Vortex Optics Razor HD AMG 6-24×50 EBR-7B FFP MRAD off my Savage 10FP in 6.5mm Creedmoor, but I didn’t want to have to remount the scope in the rings.

I initially tested the barrel using Hornady 224 Valkyrie 88gr ELD Match ammunition.

Of course, I wanted to use the Federal Premium Gold Medal 224 Valkyrie with the 90gr Sierra Match King, but these were sold out all over at the time I was looking to get the ammunition. From what I understand, the scarce availability had to do with the fact that Federal had acknowledged that people were having bad results with the Federal 224 Valkyrie 90gr SMK ammunition, and was investigating the issues. Just days after I received a few boxes of the Hornady 224 Valkyrie 88gr ELD Match, I got a notification from Target Sports USA that the Federal Premium 224 Valkyrie 90gr SMK was in-stock, so I ordered several boxes.

Note: I am a frequent customer of Target Sports USA because they are one of the few retailers that recognizes the California ammunition exemptions, and will actually ship ammunition to those California residents that are exempt from online ammunition purchasing laws.

I had the opportunity to hit the range on Halloween with a day off from work, but only had the Hornady ammo in-hand since the Federal Premium ammo was still in transit. The first twenty rounds through the barrel took place on a very windy day, so the groups were not ideal. But my concern was the statistical data recorded on the Labradar.

The data for a twenty (20) round aggregate of Hornady 224 Valkyrie 88gr ELD Match ammunition out of this 24″ 1:6.5″ twist barrel is as follows:

- Average Muzzle Velocity – 2691.64 fps

- Extreme Spread – 80.96 fps

- Standard Deviation – 18.87 fps

Obviously nothing to write home about. If you watch the range session documented in Range VLOG episode 62, you will see that I shot on a windy morning and only mustered a 1″ / 1MOA group.

After I received the Federal Premium Gold Medal 224 Valkyrie 90gr SMK ammunition, I hit the range again to get more data. Sadly, the ammunition did not shoot very well at all.

As documented in Range VLOG episode 63, the groups were terrible, roughly 1.5″ (1.5 MOA) at 100 yards. The chronograph data was slightly better than Hornady 224 Valkyrie 88gr ELD Match ammunition. A twenty-three (23) round aggregate of Federal Premium Gold Medal 224 Valkyrie 90gr SMK ammunition out of this 24″ 1:6.5″ twist barrel is as follows:

- Average Muzzle Velocity – 2741.75 fps

- Extreme Spread – 56.21 fps

- Standard Deviation – 14.46 fps

I was able to get out to the Desert Marksman Rifle and Pistol Club shooting facility and test both the Hornady 224 Valkyrie 88gr ELD Match and Federal Premium Gold Medal 224 Valkyrie 90gr SMK at 200 yards.

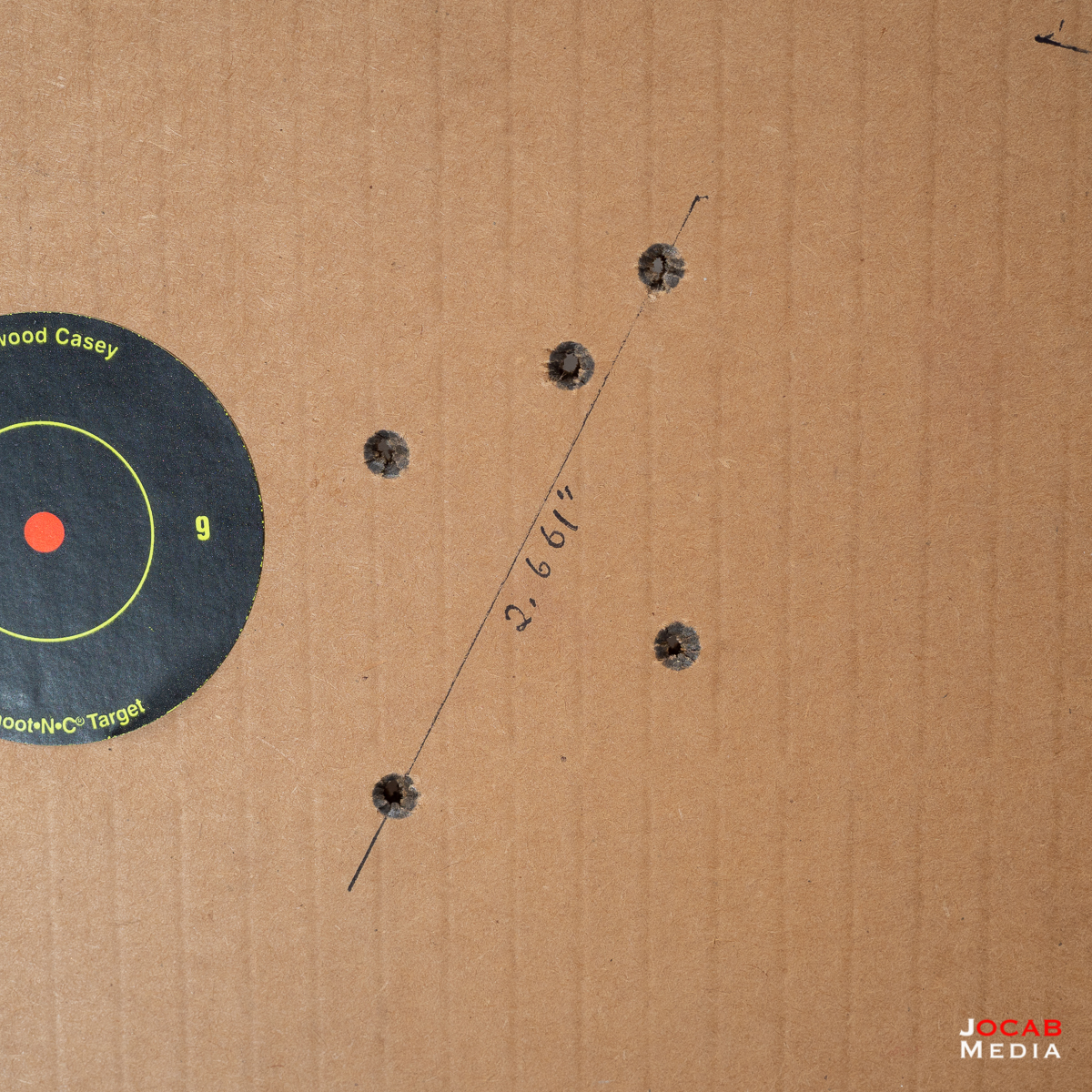

The following groups were the Hornady 88gr ELD Match at 200 yards. Aside from the first group (left), you can see how the ELD Match is shooting under 1MOA.

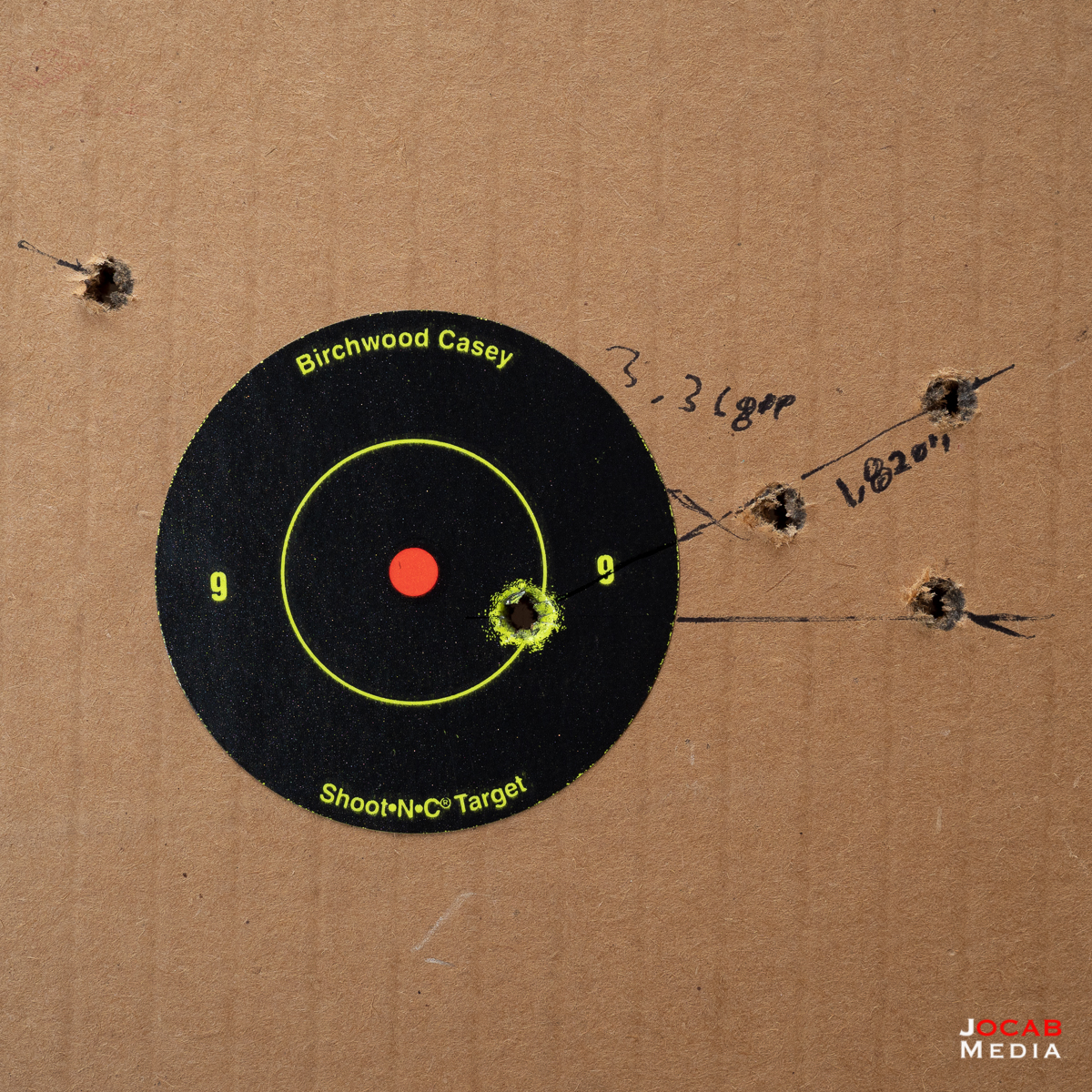

What is more interesting is the groups for the Federal Premium 90gr SMK.

It is important to note that the light conditions during this session were not ideal due to shooting straight into the sun. The windage dispersion is shooter error, but you can see how the Federal 90gr SMK is leaning towards shooting under 1MOA. If you discount the errant left shot on each of the above groups, the size of the group is respectable for 200 yards. The vertical dispersion is about 1 to 1.25″ tall.

Overall, I think this 224 Valkyrie mini-project is somewhat interesting, but not all that exciting. Of course, if this rifle were shooting one-hole groups, I would be more enthusiastic about it.

The notable aspect of this mini-project is the lack of handloading. I did not acquire dies and wasn’t planning on getting any until I figured out if the rifle can even shoot decently with factory ammunition and I am not spinning off jackets.

The rifle shoots so-so and I am definitely not spinning off jackets. So I may end up getting some dies in the next couple months and try handloading some 90gr Sierra Match Kings.

Should you buy or build a 224 Valkyrie rifle? I am going to have to say no, I would not recommend it. Unless you want to shoot 800 yards and beyond and have to do it with the AR platform, I think the 224 Valkyrie is not a cartridge for you. 6mm cartridges have so little recoil as it is and the selection of bullets is incredibly good in the .243″/6mm diameter, so I would look into cartridges like 6mm Creedmoor, 6XTC, 6mm BR, or even a high-twist barrel .243 Remington if you are on a bolt rifle platform.

Given the decreasing cost of entry into a quality (semi-)custom bolt rifle, people will trend towards bolt rifles and the flexibility of a bolt action receiver platform, and not have to be constrained by an AR-15 form factor.

I also think the high speed 22cal cartridge trend is probably going to fade quickly. Obviously, this is simply my opinion, but I think people will dabble in 224 Valkyrie for a while, and lose interest. Then the cartridge will eventually go the way of 6.8 SPC.

Nathan Spence

Thanks for sharing your experience, and good write up. Your results seem to be a common theme with the .224 Valkyrie in the AR platform.

2019 SHOT Show After Action Report – Part 6 – ocabj.net

[…] of you may have seen in my previous Range VLOGs or read in a mini-project write-up that I put together a 224 Valkyrie AR upper that has been lackluster so far (granted, I have not experimented with handloads, yet; need to buy […]